This introductory workshop is part of the NERDIC Industry 4.0 Readiness Ecosystem program for small manufacturing enterprises in the defense supply chain. For more information, please visit ccat.us/NERDIC.

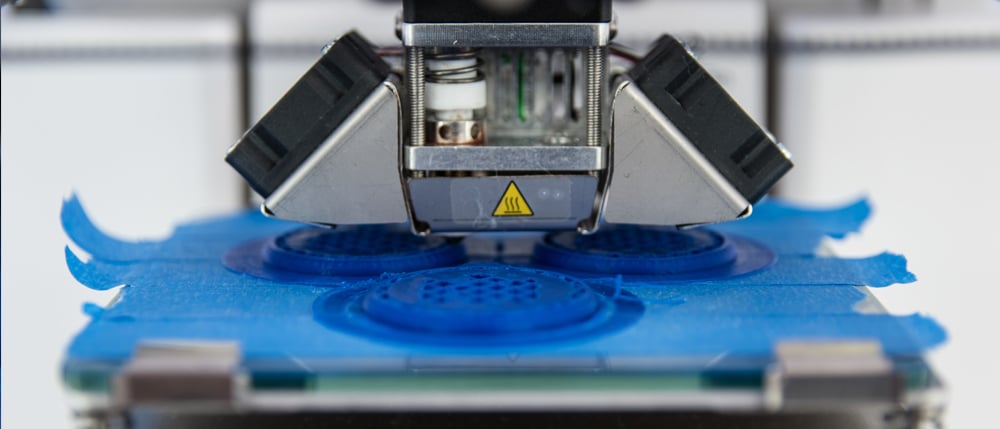

Valued at a $7.3-billion worldwide market value in 2017, additive manufacturing (AM) is disrupting multiple markets by enabling engineers to rapidly manufacture parts having substantial geometric freedom. Unfortunately, this geometric freedom is often realized with materials having insufficient properties (e.g., stiffness, strength, melting temperature) for production requirements. Addressing this problem, the rapidly-growing additive manufacturing of metals (AMM) sector now includes multiple processes, including Powder Bed Fusion (PBF) and Bound Metal Deposition (BMD). This presentation will review PBF and BMD AMM processes, resulting material properties, design principles, case studies, and economic considerations.

Learning Objectives

By the conclusion of the presentation, attendees will:

• Understand the advantages and disadvantages of PBF and BMD AMM processes

• Recognize how AMM process and design advantages can add value within supply chains while increasing part functionality

• Reflect upon their current portfolios to determine candidate AMM applications

Presenters

Dr. Brett Ellis, Associate Professor, Co-Director- Center for Additive Manufacturing of Metals, University of Maine

John Belding PE, Director- Advanced Manufacturing Center, Co-Director- Center for Additive Manufacturing of Metals, University of Maine

Christopher Paulk, Director, Vermont Manufacturing Collaborative (VT-MC), Vermont Technical College

Participants will be invited to apply to participate in a pilot demonstration project utilizing this technology. A Technology Demonstration follows this workshop and is scheduled for Tuesday, August 31, 2021 from 12 N – 1:30 pm.

Also, see this link for additional workshops in this series under “Upcoming Events”.

For more information, contact Jill Duddy at (603) 226-3200 or jilliand@nhmep.org.